Thermographic Drone inspections on Photovoltaic Solar Panel Systems are primarily used to:

– Identify, during normal solar load, defective cells with temperatures above the maximum working temperature (normally around 85 °C).

– Identify defects in the connections between cells and protection diodes.

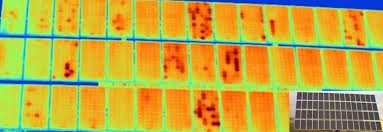

– Assessing losses of efficiency on panels with non-uniform distribution of temperatures due to cells or groups of cells with higher temperature than normal.

What are the advantages of Thermographic Drone Inspections:

A single malfuntioning cell can compromise the entire system causing economic damage. The photovoltaic modules are key components of the system because responsible for the conversion of solar radiation into electricity. A good monitoring module is therefore crucial for a timely and effective maintenance of the system, so as to obtain the best possible performance and better return on investment.

Defects of the photovoltaic modules can be visible to the naked eye such as delamination, cracking, yellowing, misalignment, corrosion and oxidation. These defects can be detected with a photo / video camera and are often due to adverse environmental conditions such as salt, hail, snow, dust, corrosive gas. Other defects are difficult to detect these are the ones that most affect the performance of a plant and can be better inspected with the aid of thermal cameras. The thermal images detected with IR cameras consist of a map of colors which indicate the surface temperature of, in this case a panel.

Analist Group has developed a CompleteThermographic Drone Solution: Phantom 336-IR which is the professional tool for thermogarphic inspections.

Procedure for IR data acquisition

- Site analysis and flight planning;

- Flight execution with automatic procedure and image acquisition (IR video/photo)

- Image processing, analysis and interpretation;

- Targeted intervention planning

Technical details

- Equipment used: Phantom-336-IR Solution with integrated thermal camera

- Shooting sequence: 1 frame every 3 seconds

- Flight time: 15 minutes

- Speed: 3m per second

- Surveyed area:: about 2 hectares

- Data obtained: Orthomosaic, IR video/photo

The different types of thermal cameras which can be used are the Radiometric or the Non-radiometric cameras.

Non radiometric thermal cameras, essentially supply a thermal image which shows the temperature differences, but it is not possible to measure the temperature exact value. That is, if you want the exact value of a spot on the image there is no way you can do this.

Radiometric thermal cameras enable you to measure the temperature absolute value of a point in the image. As a matter of fact the image is built on a matrix of a certain number of pixels on a certain number of lines. The device rapidly detects the energy stored in every pixel of the object we are observing. The higher the number of pixels the more details we have, as radiometric thermal cameras can measure the absolute temperature of every pixel.

Read more about the difference between Radiometric and Non-radiometric cameras